What is a stamping die?

Dies are essential to the modern manufacturing industry. The interchangeability of parts is what makes modern manufacturing such an important influence on our current high standard of living. This is due to dies which allow manufacturers to mass produce functionally superior and affordable products.

So what exactly are dies?

Dies are tools designed and built to accomplish specific manufacturing tasks. By themselves, they are generally incapable of performing their intended task; they need appropriate machine tools to deliver results.

What is a stamping die?

Stamping dies are specialized, high-precision tools that cut and shape sheet metal parts with the help of pressure supplied by stamping presses. They are used to mass-produce sheet metal stamping.

These dies are securely fastened to the bolsters of stamping presses. Sheet metal strips or coils are fed to the dies, either mechanically or manually. Presses provide the required pressure, and finished or semi-finished parts are produced depending upon the die types.

Die designers use computer-aided design (CAD) software to conceptualize and develop designs. Skilled diemakers then build stamping dies in accordance with the design prints.

Stamping dies are part-specific and highly precise. They are expensive and take considerable time to build because of the exacting standards required in designing and building them.

What is the purpose of stamping dies?

Modern manufacturing requires that parts be produced in huge volumes, at high production rates, at lower per-piece costs, and with repeatable dimensional accuracy.

Dies used in conjunction with stamping presses help manufacturers achieve these objectives. Therefore, they are widely used in various manufacturing industries.

Why is it called “tool and die”?

In the context of manufacturing, tools are divided into the following four categories:

- Hand tools: This category includes all implements used with physical power. Examples: spanners, pliers, pincers, wrenches, etc.

- Power tools: This category includes all stationary and portable machine tools. Examples: lathe machine, milling machine, drill press, all hand-held portable power tools, etc.

- Tooling: This category includes all tools that are used in machining processes. Examples: drills, single and multi-point cutting tools, saw blades, cutters, etc.

- Dies: This category includes devices that shape materials in various ways. Examples: stamping dies, powder compaction dies, forging dies, plastic injection molds, metal casting molds, etc.

Stamping dies are a subcategory of the main category of tools. This means that all tools are not dies but all dies are tools. On the factory shop floors, workers have been traditionally using the terms “tool” and “die” interchangeably. It didn’t seem inappropriate. After all, generally speaking, most toolmakers are also good diemakers due to a striking similarity between the two skill sets. Therefore, it has been a convention to refer to the field of the die as ‘tool and die’.

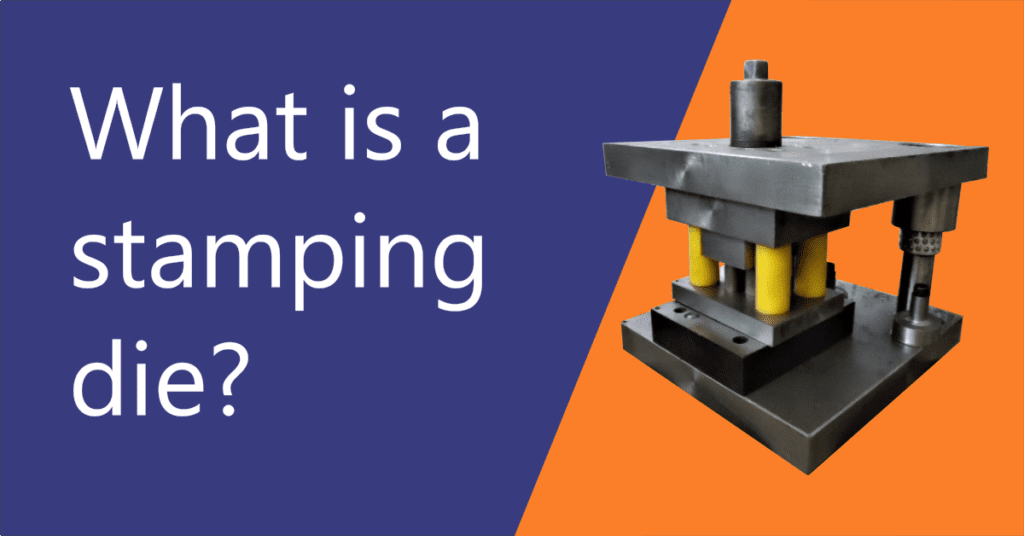

What are the various parts of a stamping die?

A typical stamping die is made up of many parts. But the number and type of the die parts vary from die to die.

This is because there are many different stamping processes, each requiring a customized die. Further, multi-operation dies require parts different from those required in single-operation dies.

However, no matter what the type and the construction of the die are, some parts are common to all dies. The common parts are:

- Shank

- Upper shoe

- Lower shoe

- Guide posts

- Guide bushes

- Dowel pins

- Punch

- Punch plate

- Die block

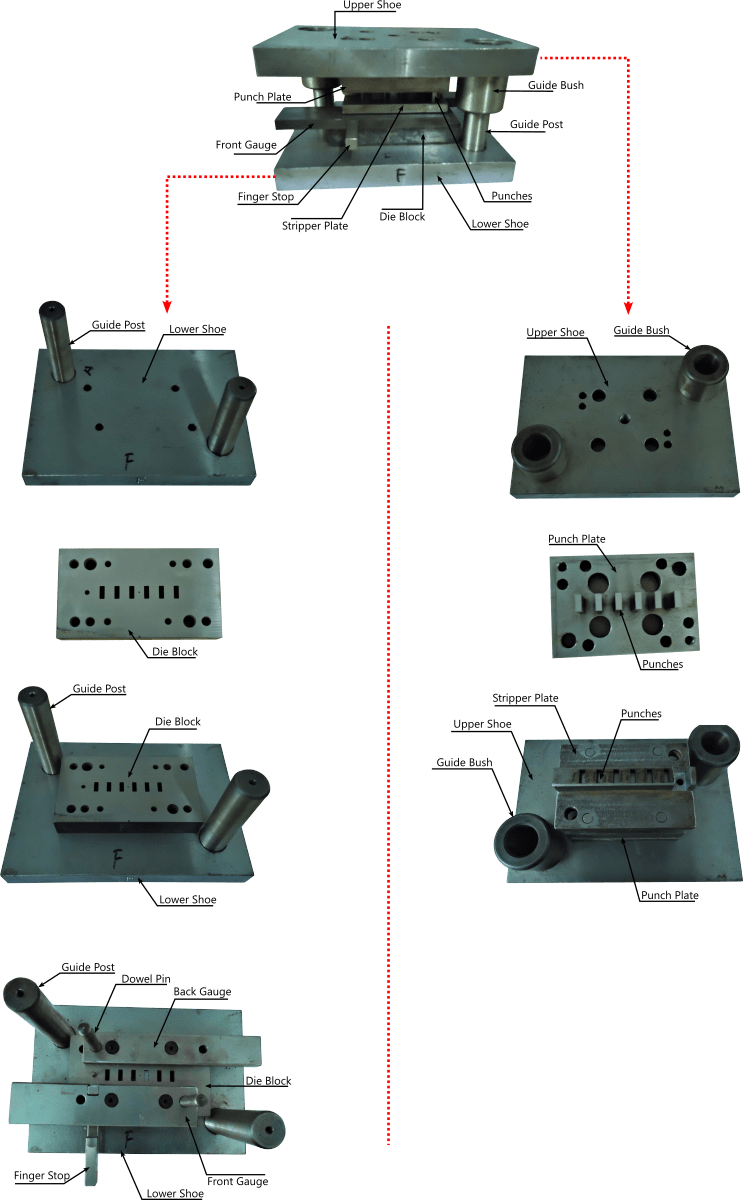

The following image shows a die and its component parts. It’s a die for cutting operation. It pierces (cuts) six rectangular windows (openings or holes) with each hit of the press.

A ‘decoiler’ unwinds the copper coil. The coil advances to the left through a predetermined distance called progression or pitch, with the help of a pneumatic feeder (not shown in the picture). The punched coil gets wound on a ‘coiler’. Here, the end product isn’t a component or part. It’s a punched coil. I designed and built this die in 2013. The production continued till 2019.

The shank, not shown in the picture,. is a cylindrical piece of mild steel (low carbon steel) with a hole in the center. It is used to fasten the upper assembly of the die to the press ram (slide). The outer diameters are made only slightly smaller than the diameter of the hole in the ram so that shanks slide smoothly into the ram hole.

Many stamping shops don’t consider the shank as a part of the die. This may be due to the practice of using the same shank for different dies that are always mounted on a particular press.

The complete assembly shown at the top is the die. However, it’s not uncommon to hear people from the stamping community call it a ‘press tool’ or ‘stamping tool’. This is not incorrect. Again, the connection with the main category is evident here. Also, many a time, the die block is referred to as ‘die’. It may sound confusing to a novice, but an experienced tool and diemaker has no problem distinguishing the contexts.

The lower die assembly with its various parts is shown on the left. It comprises parts like die block, lower shoe, guide posts, front and back gauges, nests (locators) , various stops , etc.

The upper die assembly with its various parts is shown on the right. It comprises parts like top shoe, guide bushings, punch(es), punch plate, stripper plate, etc.

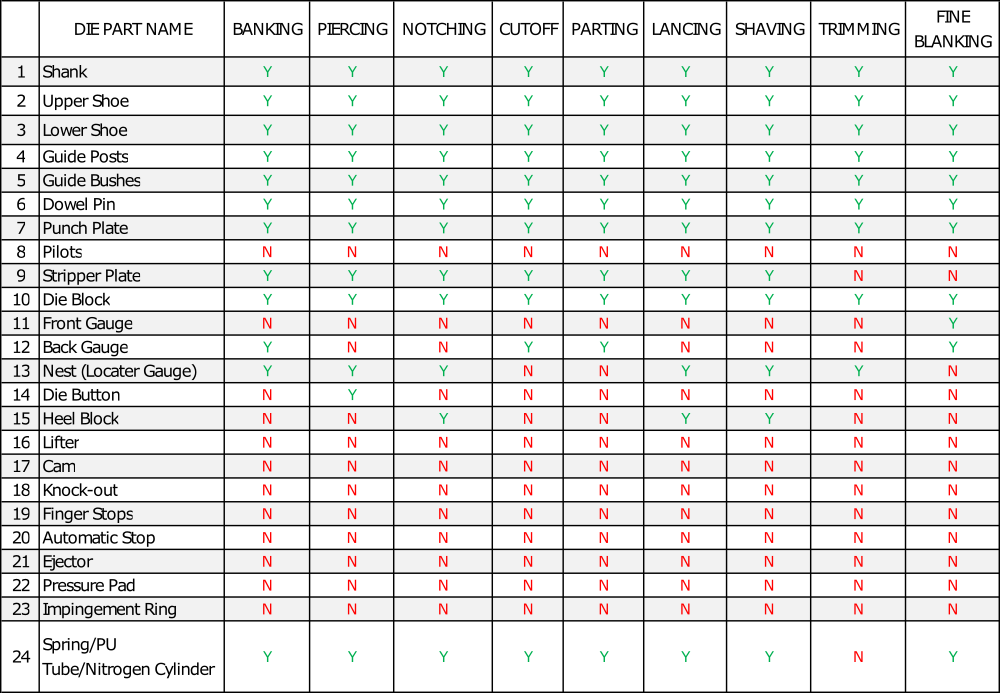

Parts of cutting dies

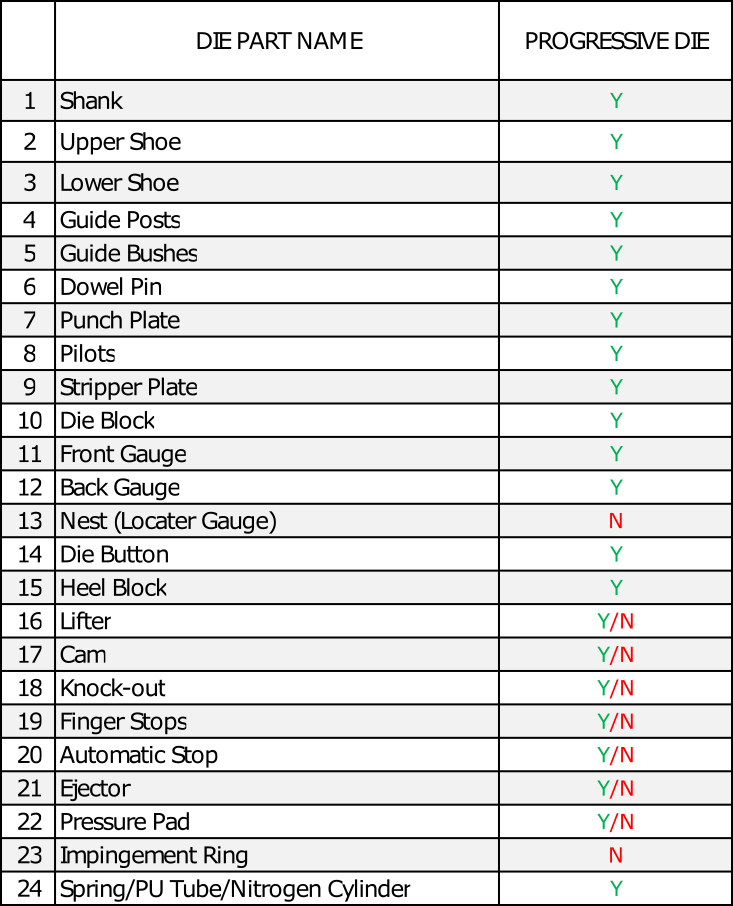

The following table shows all the parts various cutting dies consist of. ‘Y’ and ‘N’ stand for yes and no respectively.

Since cutting operations are remarkably distinct from other stamping operations, it is easy to see that cutting dies don’t have parts that a typical forming or bending die has.

Even among the various types of cutting dies, parts differ from die to die. For example, no cutting die except the fine blanking die has an impingement ring.

Further, all secondary cutting operations require nests (gauges) to accurately locate blanks. Also, a piercing die for a large part with many holes located at great distances from one another will make use of die buttons to save on expensive tool steel material and die maintenance costs. Other cutting dies will not need die buttons.

So it’s not that all dies must have a fixed number and type of die parts.

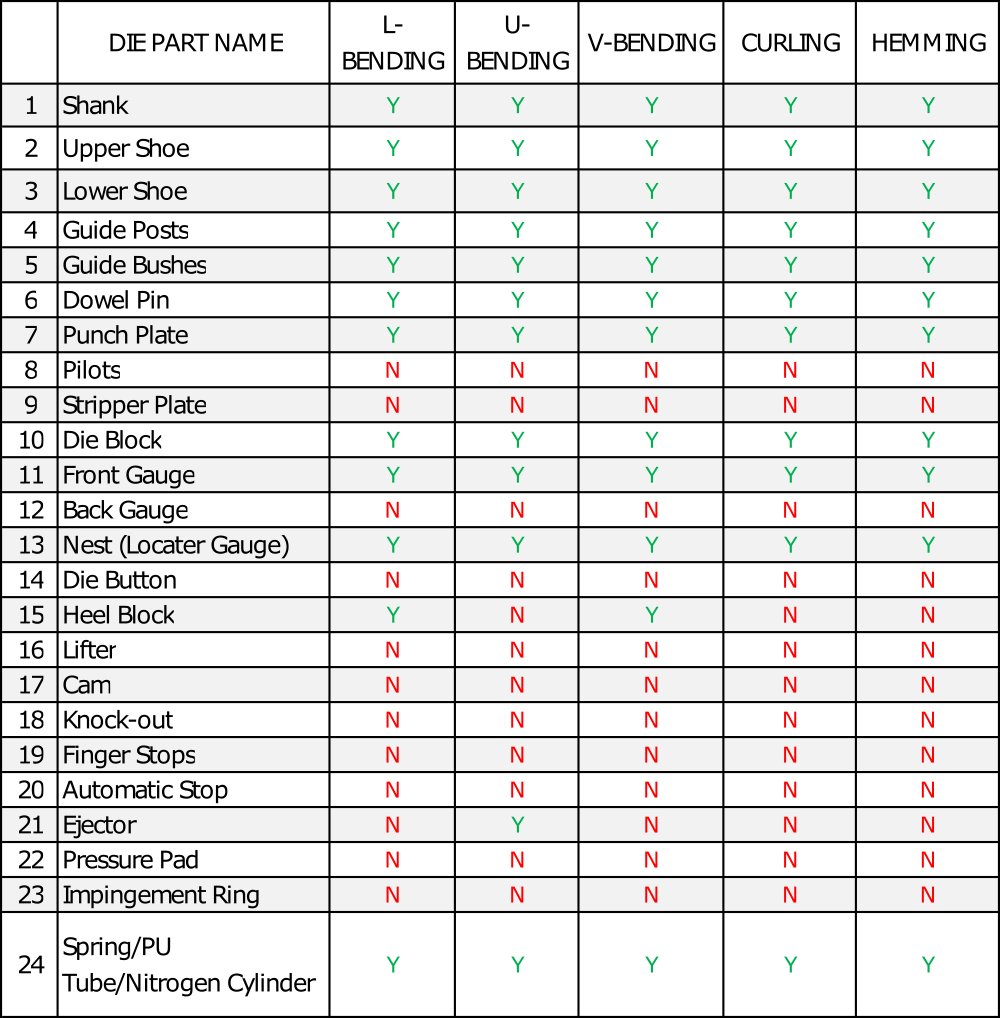

Parts of bending dies

The various parts that go into bending dies are shown in the table below.

Note that all bending dies have nests (gauges) to locate blanks with precision.

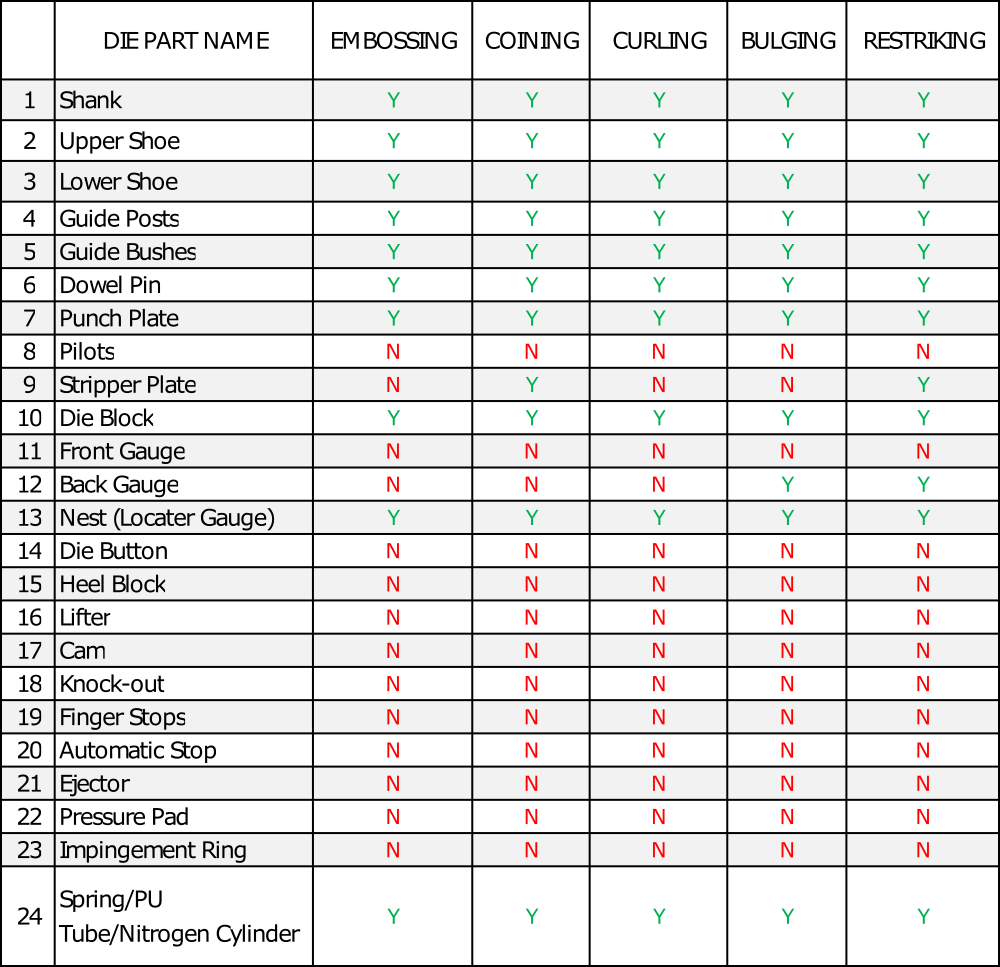

Parts of forming dies

The various parts that go into forming dies are shown in the following table

Note that all forming dies have nests (gauges) to locate flat parts with precision, but some may not have the stripper plate.

Parts of drawing dies

The various parts that make up the drawing dies are shown in the following table

Note that the pressure pad (pressure ring) is an important part of the drawing dies, but not all types of drawing dies must have them.

Parts of progressive dies

Progressive dies are so different from conventional stamping dies that some parts have been conceived to be used only in progressive dies.

For example, a progressive die with bending, forming, and drawing operations must have stock strip lifters.

The various parts that make up progressive dies are shown in the following table. Y/N stand for ‘sometimes yes, sometimes no’.

What material is used to make stamping dies?

A die cannot be said to have been made from a single material.

Materials commonly used for making stamping dies are low-carbon steels, high-carbon steels, alloy steels, and tool steels.

The die parts made from high-carbon steels, alloy steels and tool steels are hardened and tempered to hardness values specified in the die part prints.

Each part of a stamping die has a unique purpose. Therefore, depending on the purpose, different materials are used for different die parts.

Upper and lower shoes

Together they make up the majority of the die set. They act as housing for other die parts. They need to absorb shocks from cutting operations, be rigid enough to resist deflection from bending operations, and be thick enough to provide space for the heads of the fasteners.

For these reasons, they are made from materials like cast iron, cast steel, mild steel, and EN-8 low-carbon steel. They are not heat-treated.

Guide posts and bushes

Their collective function is to provide precise alignment between the upper and lower sub-assemblies of the die. They must possess good wear resistance and machinability. Therefore, they are made from case-hardening EN-353 steels (BS 815M17) or full-hardening EN-31 steels (SAE 52100) .

Punch plates and stripper plates

They are made from mild steel or EN-8 to save on expensive tool steel. Otherwise, hardenable steels EN-24 or EN-31 are usually recommended.

Punches and die blocks

These are the most important die parts. They do the bulk of the intended job.

They must be highly wear-resistant and possess a reasonable toughness. Therefore, they are usually made from tool steel like H-21 (commonly known as WPS), high-carbon high-chromium (D2) steel, and high-speed steel 1.3343 (HSS) depending upon various important factors.

Other high-performance die parts

Parts like cams and impingement rings are high-performance parts. They should be made of D2 or H21 steel.

Miscellaneous die parts

Other die parts such as gauges (front and back), nests, ejectors, lifters, and all types of stops are usually made from wear-resistant case-hardening En-353 steels (BS 815M17) or full-hardening EN-31 steels (SAE 52100).

Conclusion

Stamping dies are specialized tools designed and built to mass-manufacture interchangeable and affordable sheet metal components. They are built to exacting standards of precision and are used with stamping presses.

They are made up of more than a dozen different precision parts each assigned a unique function within the die. The die parts are made of low carbon steels, alloy steels, and tool steels depending on their function in the die.

FAQs

Are dies the same as molds?

Yes and No!

Yes, because they are the same in terms of the functions they perform and the results they deliver. Both are instrumental in delivering parts with consistent quality across various lots making part interchangeability possible. Both help transform the shape of materials.

However, unlike in dies, parts of molds are stationary and have no male and female elements. Molds can be termed as the equivalent of dies in the field of manufacturing such as plastic processing (injection molding) and metal casting.

Some people in the stamping die community do refer to dies as molds though.

How are sheet metal stamping dies designed?

The design of stamping dies begins with the stamping part print. The part’s geometry, dimensions, tolerances, material, application, and other notes mentioned on the part print are first studied and understood thoroughly.

The die designer, using his intellect and experience, determines the number and types of stamping processes the part will go through so it can be produced in the required quantities, at reasonably lower costs, and better production rates.

These considerations pave the way for determining the number and types of stamping dies that need to be built. He/she then proceeds to design the dies using CAD software and simulation software. CAD software is not a substitute for human creativity but they do help increase design productivity.

Throughout the design process, inputs are sought from stamping designers, manufacturing engineers, and diemakers. The collective knowledge, information, experience, and wisdom help refine the designs of the dies.

Which section of an industrial organization is responsible for building stamping dies?

The tool room. It’s manned with skilled machinists, fitters, turners, and other craftsmen. A highly skilled and experienced diemaker heads it.

Each part of the die is laid out by the die designer in great dimensional detail in the die part prints.

It’s the responsibility of the tool room staff to build die parts to conform to the print, assemble them, inspect the final assembly, and actively participate in die tryouts on the shop floor.

What are the standard die parts that can be purchased off the shelf?

There are quite a few die parts available for off-the-shelf purchase. Die sets, HSS (high-speed steel) round punches, guide posts, guide bushings, ball-bearing sleeves, and dowel pins are some of them.

How many sets of dies are made for a typical sheet metal stamped part?

Dies are very expensive to make; take up a lot of time and effort; and are very part-specific. Therefore, investing resources in multiple sets of dies for a part is a major investment decision.

Generally speaking, only one set of dies is made in most cases. However, when a part is very critical to huge volume production of an end product (for example, an automobile), a standby set of dies is also made. This helps avoid potentially huge financial losses that may result from a long interruption in the assembly line due to a breakdown in critical part’s die.